When researching premium window options for your Colorado home, you’ll likely encounter two advanced materials: Ultrex® fiberglass, used in Infinity from Marvin®, and extruded aluminum cladding, featured in Marvin Signature® Ultimate. Both represent significant upgrades over basic vinyl, yet they take fundamentally different approaches to construction, performance, and long-term resilience.

Understanding how these materials behave — especially in Colorado’s demanding environment of high UV, large temperature swings, and sudden storms — can help you choose windows that remain strong and beautiful for decades.

Ultrex® Fiberglass: Engineered Strength with Lasting Stability

Material Composition:

Ultrex fiberglass is a

pultruded composite made by pulling continuous glass fibers through a resin bath and heated die, producing a dense, stable profile. Developed specifically for windows, Ultrex delivers strength, consistency, and low thermal expansion.

Technical Advantages:

- Low Thermal Expansion: Expands and contracts at nearly the same rate as glass, minimizing stress on seals and joints.

- Structural Strength: High strength-to-weight ratio enables slender frames and expansive glass areas.

- Thermal Efficiency: Fiberglass has low thermal conductivity, contributing to strong energy performance when combined with insulated glass.

- Corrosion Resistance: Impervious to rot, rust, and moisture damage — ideal for mountain and high-altitude climates.

Practical Considerations:

- Durable Acrylic Surface: The co-extruded acrylic cap provides long-term UV stability and color retention.

- Factory Finish: Available in multiple factory-applied colors for lasting uniformity; field repainting is rarely needed.

Repair Approach: Fiberglass can be repaired professionally if damaged, though surface color matching requires factory materials.

Extruded Aluminum Cladding: Architectural-Grade Exterior Protection

Material Composition:

Extruded aluminum cladding is formed by forcing aluminum billets through a die under pressure, producing strong, consistent profiles. Marvin’s extruded aluminum is up to three times thicker than roll-form aluminum and finished with high-performance coatings validated to

AAMA 2605 high-UV performance standards and

verified by third-party testing.

Technical Advantages:

- Impact Resistance: Exceptional strength against hail, debris, and weather events.

- UV Durability: Validated to AAMA 2605 high-UV performance standards for fade and chalk resistance.

- Refinishable Surface: Can be repainted using compatible high-performance coatings for color updates.

- Commercial Heritage: The same finishing technology used on commercial buildings ensures lasting stability.

- Wood Protection: Completely shields the wood interior from exterior weather exposure.

Considerations:

- Thermal Conductivity: Aluminum conducts heat, so Marvin uses

engineered thermal breaks to separate the interior wood from exterior metal.

- Weight: Heavier than fiberglass, requiring robust hardware and precise installation.

Cost: Higher initial investment, offset by long-term durability and refinishability.

Performance in Colorado Conditions

UV Resistance and Longevity

At Colorado’s elevation, UV exposure can be roughly 25 % higher than at sea level — a true test for exterior materials.

Ultrex® Fiberglass with Acrylic Finish:

- Proven UV stability through decades of field exposure.

- Factory-applied acrylic finish resists fading and chalking when cleaned periodically.

Extruded Aluminum with AAMA 2605 Finish:

- Validated to AAMA 2605 high-UV performance standards.

- Refinishable if color changes are desired after many years.

Both systems are engineered for long-term color retention; the difference lies mainly in the surface technology — fiberglass’s integral acrylic layer versus aluminum’s commercial-grade fluoropolymer coating.

Hail and Impact Resistance

Colorado’s Front Range is notorious for hail.

Ultrex® Fiberglass:

- Resists normal impact without deformation.

- Severe hail can chip or crack the surface, requiring professional refinishing.

- Structural integrity remains high even with surface damage.

Extruded Aluminum:

- Provides added dent resistance in severe hail regions and is a preferred choice in regions with frequent hail, based on field performance.

- Minor dents typically do not affect performance and can often be repaired.

- Impact resistance based on material rigidity and field data; not certified under specific hail-impact standards.

Excellent option for homeowners seeking durable, long-term exterior protection.

Thermal and Energy Performance

Ultrex® Fiberglass:

- Low thermal conductivity minimizes heat loss through the frame.

- Dimensional stability keeps seals tight through freeze-thaw cycles.

- ENERGY STAR®-qualified configurations available across all U.S. climate zones.

Aluminum-Clad Wood:

- The wood interior provides natural insulation and warmth.

- Thermal breaks isolate exterior metal from interior wood.

When paired with advanced glass packages, achieves excellent whole-window U-values comparable to fiberglass.

Manufacturing and Quality Control

Ultrex® Fiberglass Production:

- Pultrusion ensures consistent profile strength and precision.

- Acrylic capping process bonds directly to the fiberglass for a unified structure.

- Manufactured under tightly controlled temperature and humidity for consistency.

Extruded Aluminum Cladding Production:

- Extrusion yields highly uniform, rigid profiles.

- Commercial-grade finishing lines apply AAMA 2605 coatings with rigorous quality checks and third-party verification.

- Dimensional precision supports architectural-grade performance.

Both systems rely on exacting quality standards — one rooted in composite technology, the other in metal fabrication and finishing science.

Maintenance and Lifespan Expectations

Ultrex® Fiberglass:

- Simple maintenance: periodic washing with mild soap and water.

- Factory finish designed to maintain appearance for decades.

- Occasional hardware lubrication recommended.

Aluminum-Clad Wood:

- Exterior requires little more than cleaning; refinishing is possible after decades.

- Interior wood can be restained or repainted to refresh aesthetics.

Long-term maintenance options are well established in both residential and commercial practice.

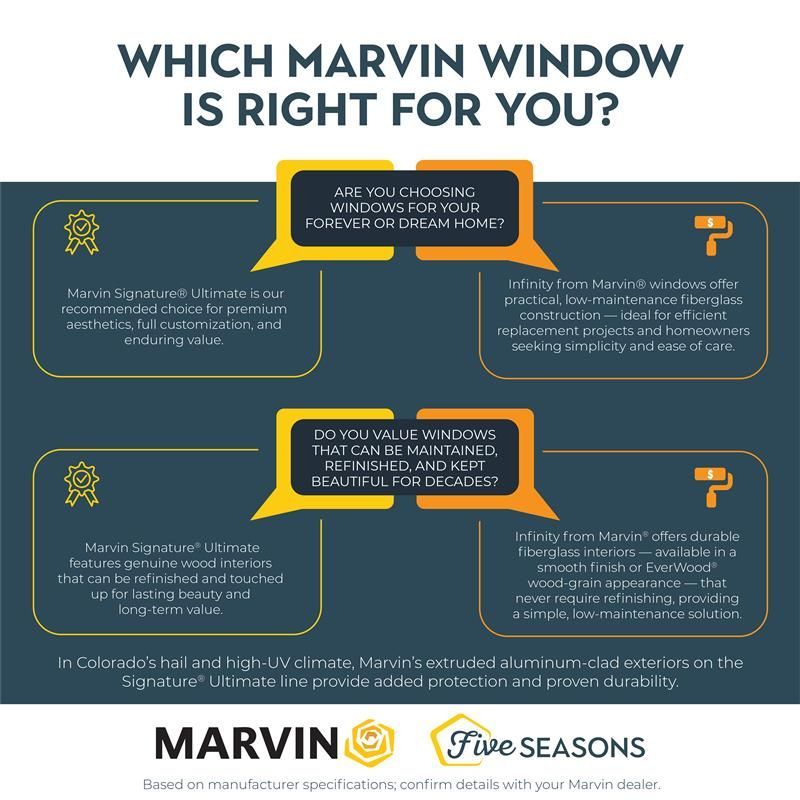

Making the Technical Choice

Choose Ultrex® Fiberglass if you want:

- Excellent energy efficiency and dimensional stability.

- Low-maintenance performance at a moderate price point.

- A clean, contemporary look for replacement or remodeling projects.

Choose Extruded Aluminum-Clad Wood if you value:

- Maximum durability and hail resistance.

- Authentic wood interiors with refinishing flexibility.

- Proven performance in extreme UV and weather exposure.

Architectural design freedom and long-term value retention.

Why Five Seasons Recommends Marvin Signature® Ultimate for Colorado Homes

At Five Seasons Windows & Doors, our field experience across thousands of Colorado installations has led us to conclude that Marvin Signature® Ultimate consistently provides the most reliable long-term performance for homes in this region’s demanding climate. This perspective comes from years of observing how different window systems respond to Colorado’s combination of altitude, UV exposure, and dramatic temperature swings.

Marvin Signature® Ultimate’s combination of real wood interiors, extruded-aluminum exteriors, and an AAMA 2605 high-performance finish verified by third-party testing delivers superior protection against UV, hail, and temperature extremes — all while offering timeless beauty and exceptional design flexibility.

Homeowners who choose Marvin Signature® Ultimate benefit from:

- A

20-year exterior finish warranty validated to AAMA 2605 high-UV standards.

- Refinishable

real wood interiors that can be restored decades later.

- Commercial-grade extruded-aluminum cladding that resists dents, chalking, and fading.

- Customizable designs to match any architectural style.

For Colorado homeowners investing in their “forever home,” Marvin Signature® Ultimate provides a blend of craftsmanship, resilience, and value that endures for generations.

Ready to explore your options?

Contact

Five Seasons Windows & Doors today to schedule a no-pressure consultation. With over 230 five-star reviews and decades of regional expertise, our team can help you find the perfect Marvin windows for your home — built for Colorado light, comfort, and longevity.

Confirm warranty details with your dealer; coverage terms may vary by component.

Get Started Today

Five Seasons Windows & Doors is Colorado’s top-rated local window company with 230+ 5-star reviews. We offer expert advice, no-pressure quotes, and flexible project options — including phased installs. Schedule your consult today.